Menu

Surface Finishing

What We Do

Surface Finishing

As part of our “one-stop shop” service capability, McKechnie® has on-site anodising and powder coating facilities.

All surface coating is done to NZ and Australian Standards. Our powder coating operation has both Dulux Prime Accredited Powder Coater status and a Gold Interpon D Approved Applicator and is subject to regular audit by both powder suppliers.

Surface Finishing

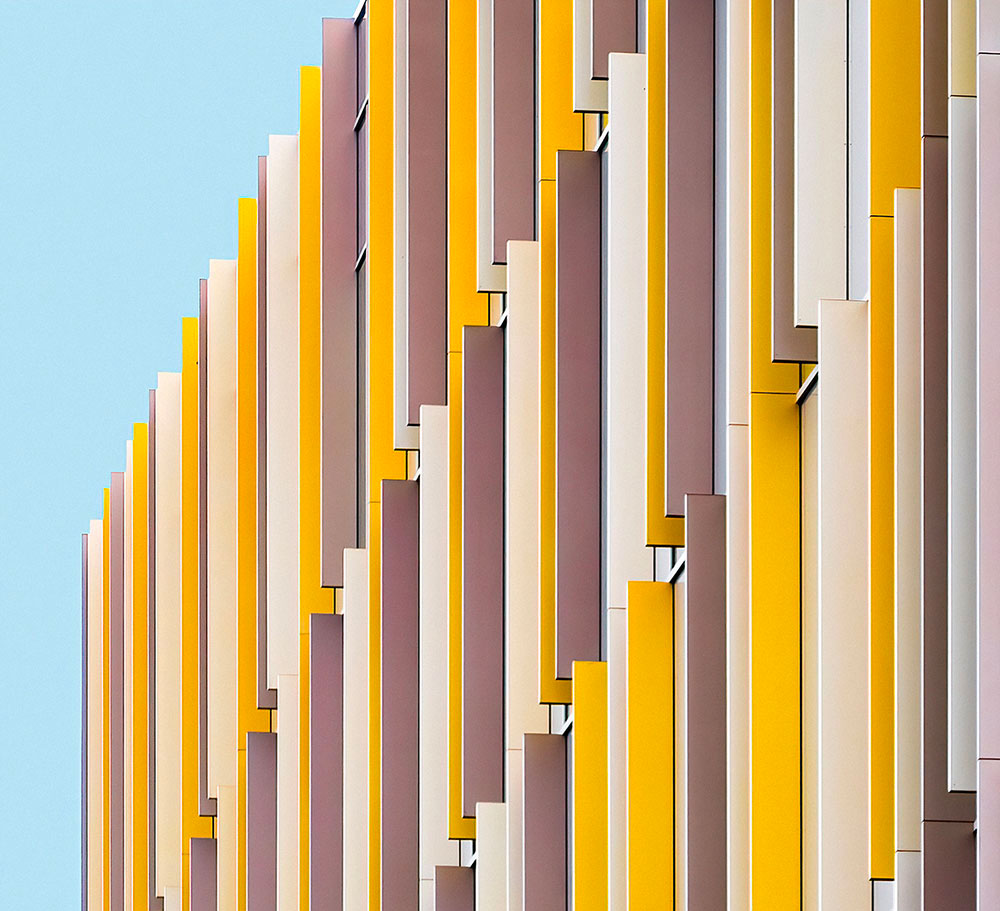

Powder Coating

We have two powder coating lines, with the second state-of-the-art line commissioned in late 2021. We offer superior powder coat finishes suitable for both industrial end use and applications requiring a higher level of finish.

We offer up to 6.5m extrusion length capability.

We offer more than 100 colours, and can produce specialty colours and formulations on request. Please contact us for more details of our colour options.

Certifications:

Dulux Prime Accredited Powder Coater

Gold Interpon D Approved Applicator

Powder Coat Lines:

Two PC Lines

- GEMA OptiSpray pumps and GA04 electrostatic spray guns ensure optimal coverage and uniformity.

- Advanced automation maximises efficiency for a flawless, high-performance finish.

- GEMA application gear - Latest proven technology for horizontal lines

- Gema - global leader in powder coat technology (Swiss)

- 10 bar loading and unloading system @ 6.5m max

- 3.0 m/min conveyor speed

- 29m cure oven @ 230C

- PC Pre-treatment plant - Semi automated with dry off oven

Standards:

- WGANZ Powdercoat - Industry Standard & AS 1580.408.4 - 2004 Paints and related materials - Methods of test "Method 408.4: Adhesion (crosscut)

- WGANZ Anodic Oxide coatings

- Various New Zealand Standards - Internal extrusions and surface finishing tolerances

Surface Finishing

Anodising for great looks that last!

Anodising is a durable and hard-wearing finish offering maximum protection in harsh environments. A range of colours are available from natural, to black and micron finishes between 12μm and 25 μm, ensuring you achieve your desired look and durability.

PEARL ANODISED FINISH

Our Pearl Anodised Finish uses a process of acid etching to give you a more uniform matte look to all visible aluminium surfaces. Pearl Anodised Finish has many advantages over standard anodising.

These include:

- A smoother surface by reducing surface defects

- A uniform look by reducing visible die lines

- Environmentally friendlier alternative to standard anodising

- A premium matte finish

- Available in Natural, Champagne, Black and a range of Bronze finishes

McKechnie® anodised extrusions comply with:

- AS/NZS 1866-1997: Aluminium and Aluminium Alloys

- AS 1231-2000: Aluminium and Aluminium Alloys - Anodised Coatings for Architectural Applications

- WANZ Specification [WGANZ SFA 3503-03-2005]: Anodic Oxide Coatings On Wrought Aluminium for External Architectural Applications

McKechnie® products are produced under the controls of ISO 9001-2015 Quality Management and ISO 14001:2015 Environmental Management.

McKechnie’s impressive Pearl Anodised finish uses a process of acid etching to produce a smooth, uniform matte look on all aluminium surfaces, whilst providing durability and hard-wearing finish. A range of colours and micron finishes are offered to ensure you achieve the desired look.

Matt Natural Anodising

For a contemporary look, natural anodising is the most popular finish. For harsh environments such as coastal or corrosive areas, natural anodising in 25μm offers the best protection. Natural Matte Anodising is available in 12μm and 25μm to suit internal and external applications.

Champagne Anodising

Where a lighter colour is more desirable, there’s a more contemporary “Champagne” shade. Our Champagne finish is available in 25μm.

Bronze Anodising

Suitable for a traditional feel or to suit darker colour schemes in architectural applications, Bronze Anodising gives a timeless and classic look, while maintaining maximum protection. Light and medium bronze anodised finishes are available in 12μm and 25μm. Dark bronze anodised finish is available in 25μm.

Black Anodising

More applicable for component and display hardware, we offer a black anodised finish available in 25μm.

Colour Variation

Variations with materials from the same batch will occur in the final product. Viewing the product from different angles and light sources will have a noticeable effect on apparent colour. Variations are exacerbated in lighter shades such as Natural finishes.

Disclaimer: Where standard caustic anodising can exacerbate imperfections in the metal, Pearl anodising (acid etch) provides a superior surface finish as it minimises serious die and bearing lines. With less aluminium oxide, our Pearl Anodising solution is also a more environmentally friendly choice.